Case

Study

Location

Keith, South Australia

Crop

Onions

Ciampa Produce, Keith SA

Ciampa Produce annually grows more than 12,000 tonnes of onions and has increased average yields from 80 to 111 tonnes per hectare over the past three years.

The Ciampa’s believe an important contributor has been an improved fertiliser strategy. This included the introduction of BioAgPhos® to the program in 2010 and demonstrated the value of a more consistent release of P over the growing season.

Phil Toy of BioAg, says progressive operators like Ciampa Produce are reaping the rewards of putting measurement into their business and tracking inputs, outputs and the returns from investments.

Phil Toy of BioAg with Ciampa Produce employees.

In the Ciampa Produce case, measurement to refine strategies includes routine fortnightly sap and petiole testing throughout the onion growing season.

Daniel Mead, first called on his brother Glen, director and agronomist of D&M Rural, to undertake a testing program to identify any barriers to healthy uninterrupted growth. “For quality onions supplied to a discerning national market, we seek good control of the variables in growth,” Daniel said.

“For quality onions supplied to a discerning national market, we seek good control of the variables in growth.”

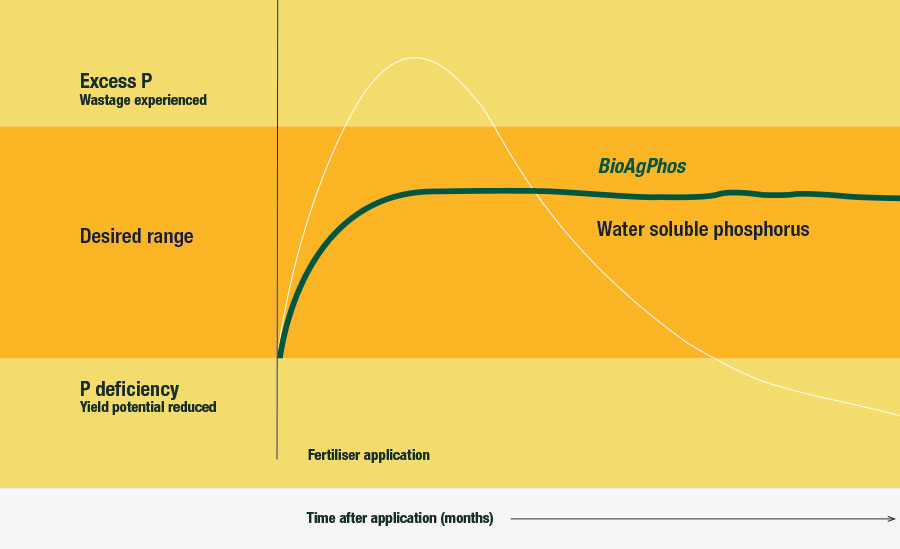

“Soil and moisture conditions, plus the weather, of course come into the picture but we had been particularly interested in getting the nutrient supply right, and with Glen’s services we were able to find peaks and troughs in phosphorus.”

Healthy growing conditions are evident even in naturally poor soil, as indicated by the moisture band and strong root growth.

Phil Toy of BioAg shows the poor structure of soil that is largely unsuitable for cereals, yet able to support productive onion crops under irrigation and a carefully formulated nutrient program.

The previous fertiliser program for P was primarily based on superphosphate. Glen’s testing identified P levels as being very high early in the life of the onion plants, followed by significant leaching away of the nutrient to form a trough. Responding with another superphosphate application to top up meant another peak in P, followed by yet another trough.

“Introducing reactive rock phosphate, with less immediately available P, in a single early application as BioAgPhos, ironed out the peaks and troughs,” Glen said. “We’ve taken out the leaching and variability and avoided going back to the crop for another application of phosphorus.”

Although the total cost of nutrient applications has been steady at about $500 per hectare the new program, based on measurement and the tracking of responses, has meant improved performance.

Glen is satisfied regarding the agronomic benefits of BioAgPhos, and believes that while there have been several factors contributing to the improved performance, ranging from use of water retention products to soil and water management, this input is the one that can most clearly be correlated with the outcomes.

“Introducing reactive rock phosphate, with less immediately available P, in a single early application as BioAgPhos, ironed out the peaks and troughs.”

Note that while BioAgPhos has proven to be the ideal means of providing P through the length of the growing season it also provides this nutrient in the critical early stages when there is high demand for P.

Phosphorus Availability – Water soluble phosphates vs BioAgPhos

Download case study

Download a PDF version of the above case study.

Recent Comments