Latest

News

Demonstrations making significant and expeditious differences

Adelaide Hills and the Riverland, South Australia

Apples in the Hills

A family-owned Apple Orchard Demonstration was set up in the Adelaide Hills, with the addition of BioAg Biostimulants on Pink Lady and Snapdragon varieties. Trees from each of the varieties are the same age, same plantation, but a different irrigation system, which allowed for the different treatments.

Application plans of treated plots were set up to promote the outcomes of healthy soil, increase water holding capacity (retention), increase ability to uptake available nutrients, minimising the impact of stress, and increase the soil microorganism network. With improving soil capabilities, the plan of the four-year trial is to improve to quality (including minimising pest impact) and quantity of the fruit.

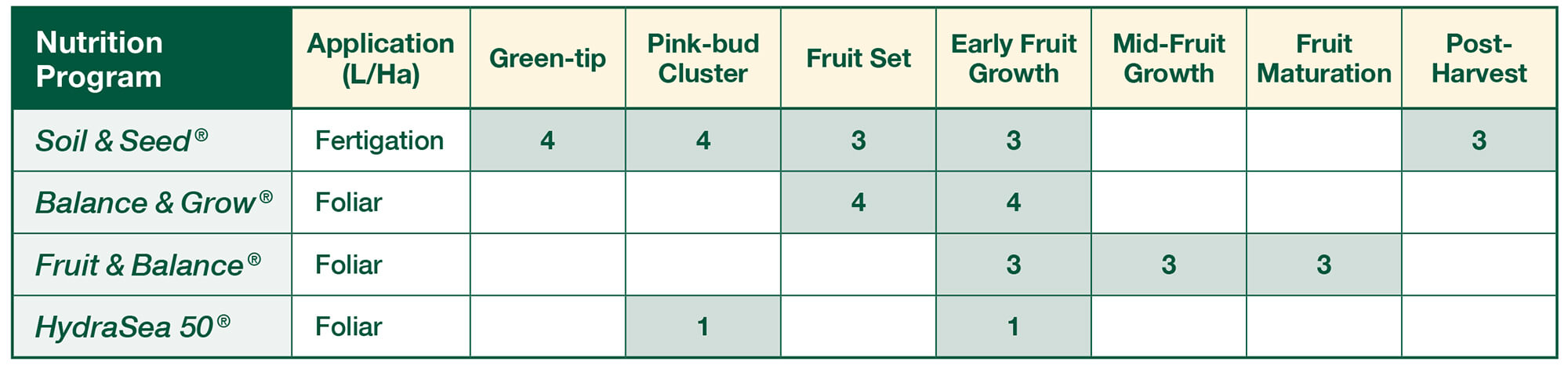

Soil & Seed® (Fertigation), Balance & Grow®, Fruit & Balance® and HydraSea 50® (Foliar) were applied throughout the different growth stages, and post-harvest to set up the carbohydrates/energy for bud burst the following season. The first application was in August 2024 (Soil & Seed).

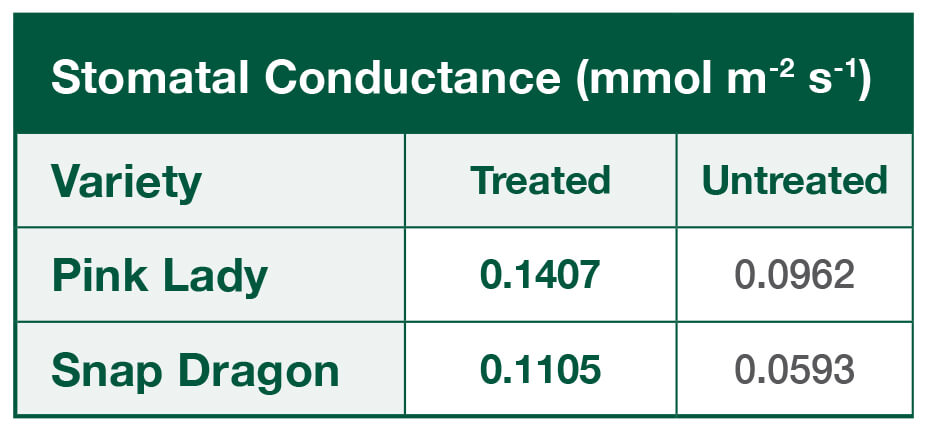

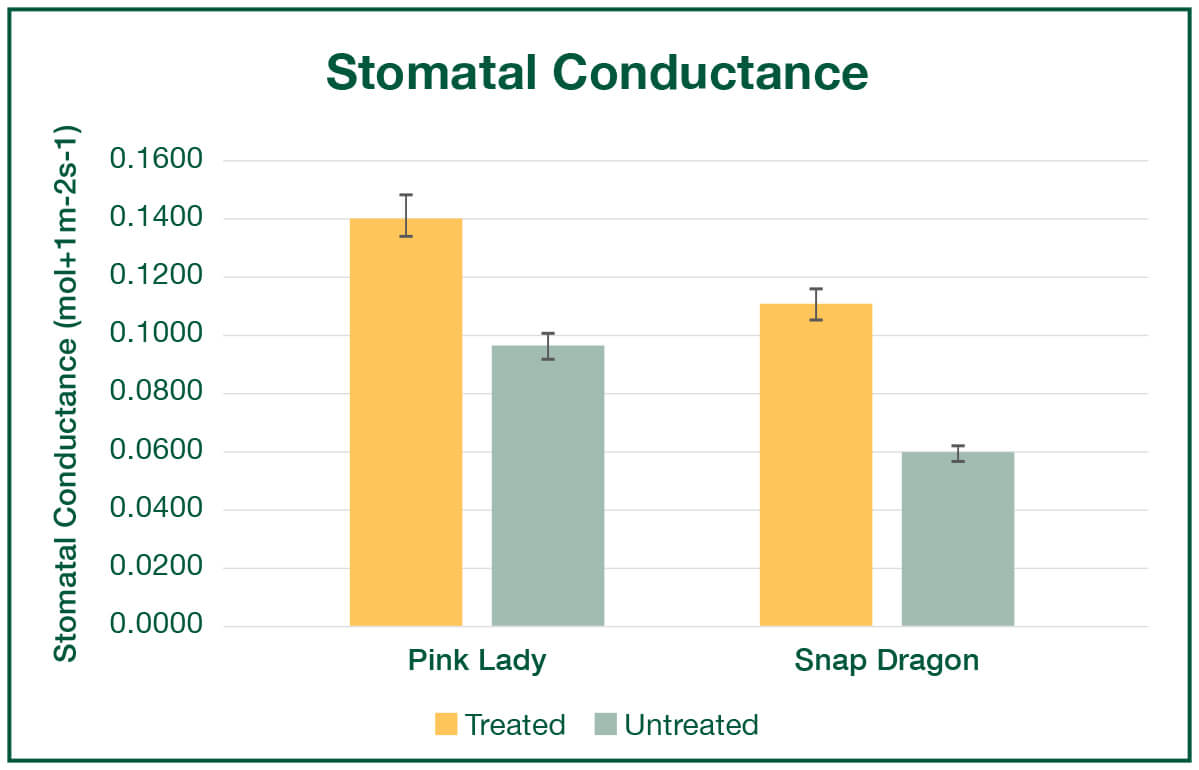

Plant physiology stresses caused from all external factors can be measured by several methods. Stomatal Conductance is a good measurement to calculate the water balance, photosynthesis rates (CO2 uptakes) and most importantly, the stress impacts. Stomatal conductance is a key factor in determining the rate of water loss and use-efficiency in apple trees.

Stomatal conductance measurements were taken at solar noon mid-April 2025 on the treated and untreated plots of Pink Lady and Snap Dragon (150 leaves evenly spread per plot), full grown, undamaged healthy leaves. All trees are cover-protected (to prevent hail and sunburn damage, and protection from birds and bats).

Table 1/Graph 1: The mean measurements of Stomatal Conductance (gs); Rate of gas exchange through stomata (mmol m-2 s-1), from Pink Lady and Snap Dragon Varieties.

T-tests were completed with the data, showing both varieties are statistically significantly different; with p-values <0.05. (Note: T-Tests determine if the difference between the means of two groups is statistically significant p-values).

These statistically significant differences between these plots, demonstrates the stress on the untreated trees, most likely from higher-than-normal temperatures and lower natural rainfall into the dams used to irrigate. Soil & Seed makes these differences by accelerating conversion of crop residues into humus; improving soil agglomeration; improving infiltration and water holding capacity, and improving nutrient solubilisation, cycling and delivery to these crops.

The orchard grower has technical devices in the orchard, including soil moisture sensors, and mentioned after the first application of Soil & Seed, “I couldn’t believe how deep that water went. I’ve never seen that, unless we have an excessive flood”.

BioAg Biostimulant applications have definitely had a positive impact during the driest spring and summer since 1991/1992 (Reference: BOM) in the Adelaide Hills and afar.

Harvesting has begun!

“I couldn’t believe how deep that water went. I’ve never seen that …”

– Apple Orchard Grower, Adelaide Hills

Almonds on the Murray

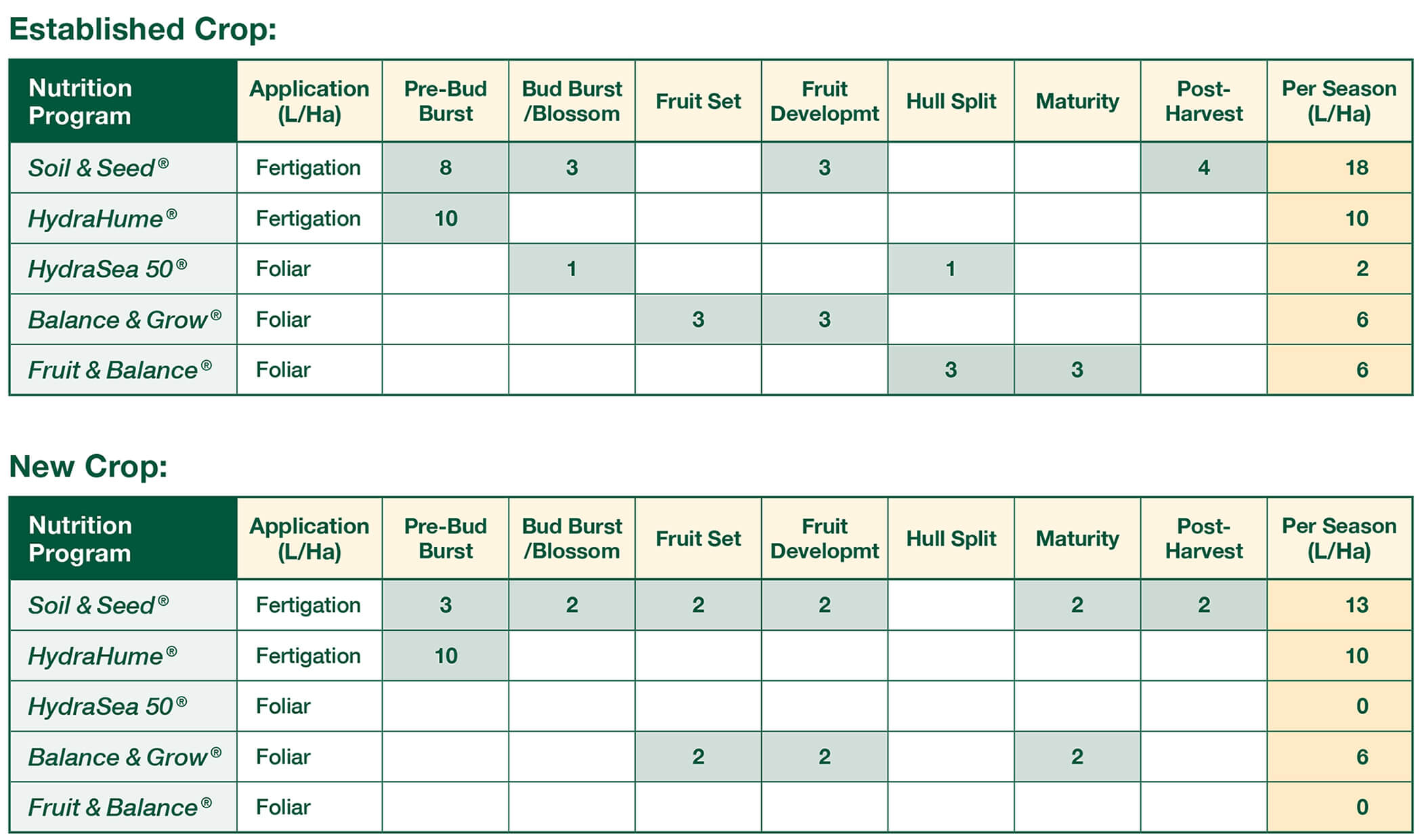

A demonstration in the Riverland was started in August 2024. In two lots (eight-year old trees and a new-planted crop), both with a treated and untreated plots. Both plots have 3 varieties, all on the same Rootstock of Nemaguard.

Application plan of treated plots was set up to promote the outcomes of healthy soil, increase water holding capacity (retention), increase ability to uptake available nutrients, minimising the impact of stress, and increase the soil microorganism network. The soil consists of 83% Sand, 8% Silt, and 9% Clay.

Note: No nut production was wanted on these new crops, to allow for growth and carbohydrate storage for the following season of production, which will be hand-picked when green. Overall growth was the main focus, hence why no Fruit & Balance® was applied.

With improving soil capabilities mentioned, the plan of the four-year demonstration is to improve to quality (including minimising pest impact) and quantity of the whole hull, shell and most importantly, the almond nut.

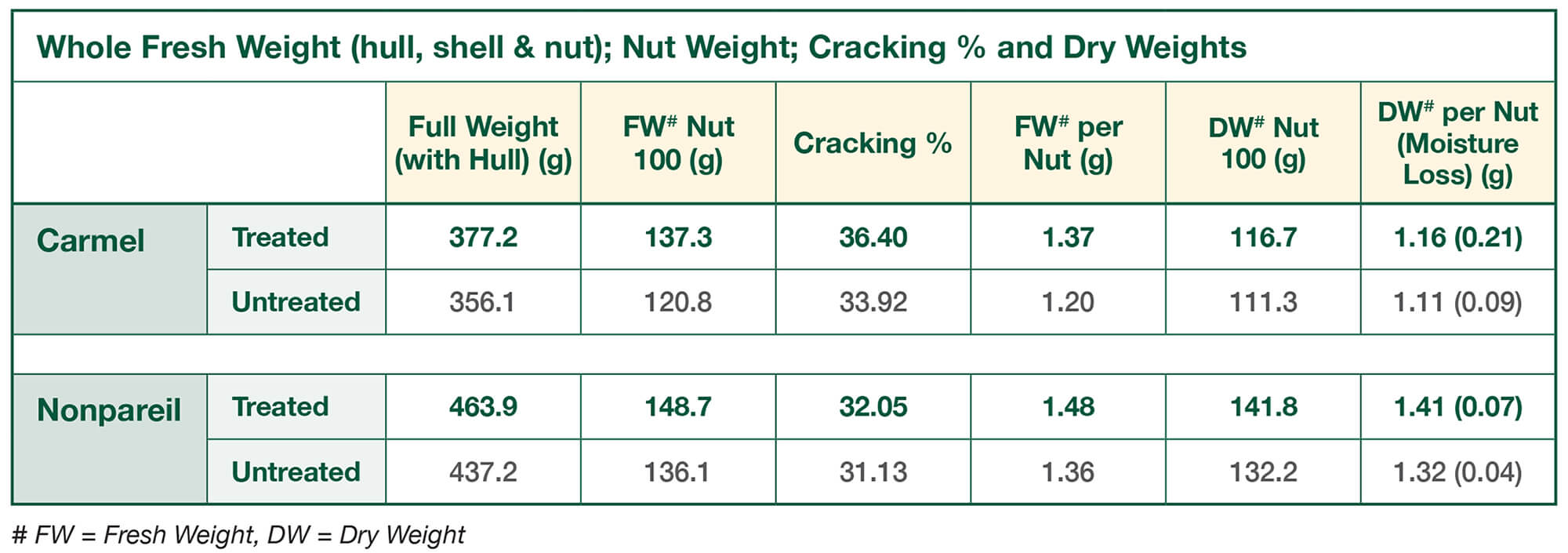

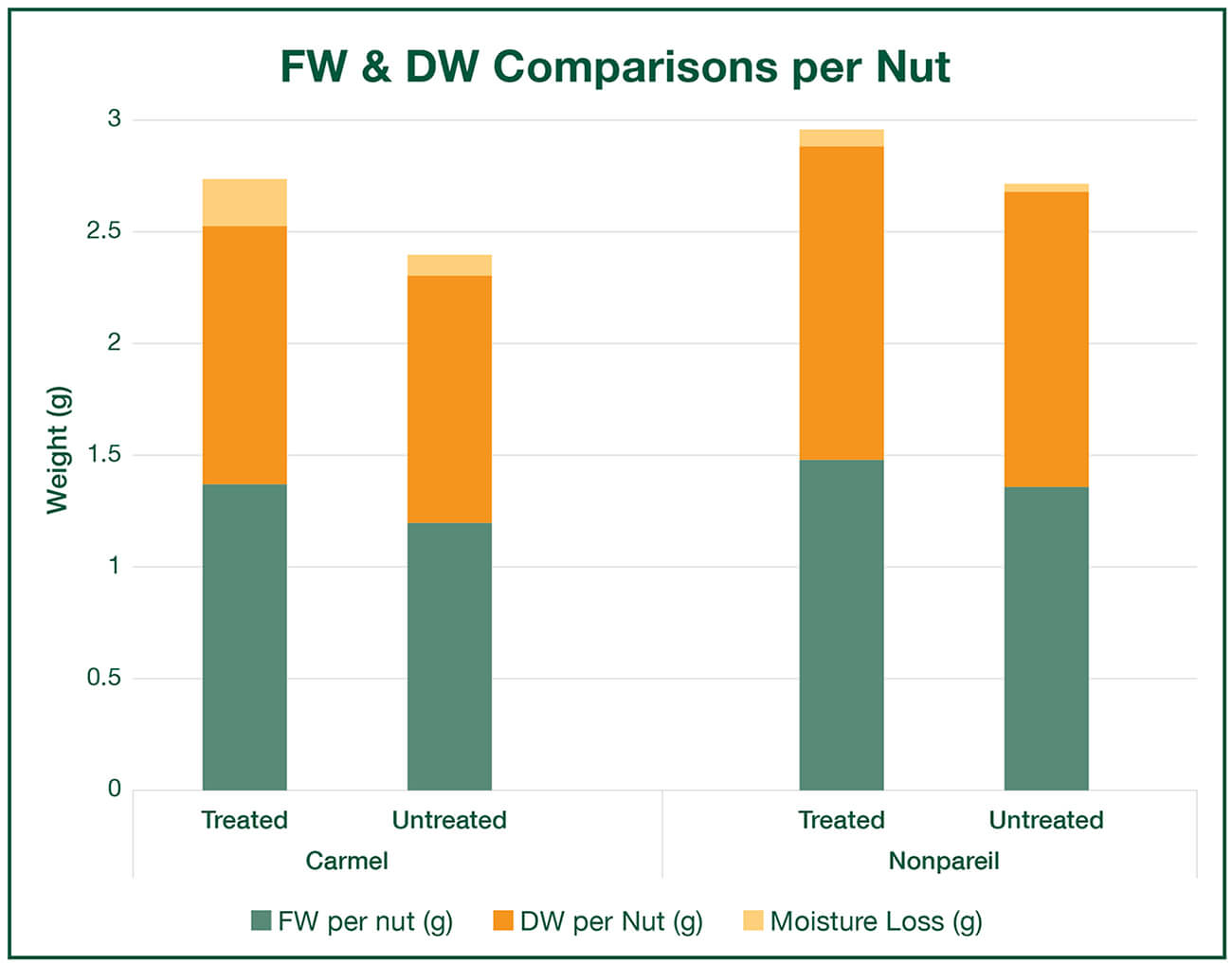

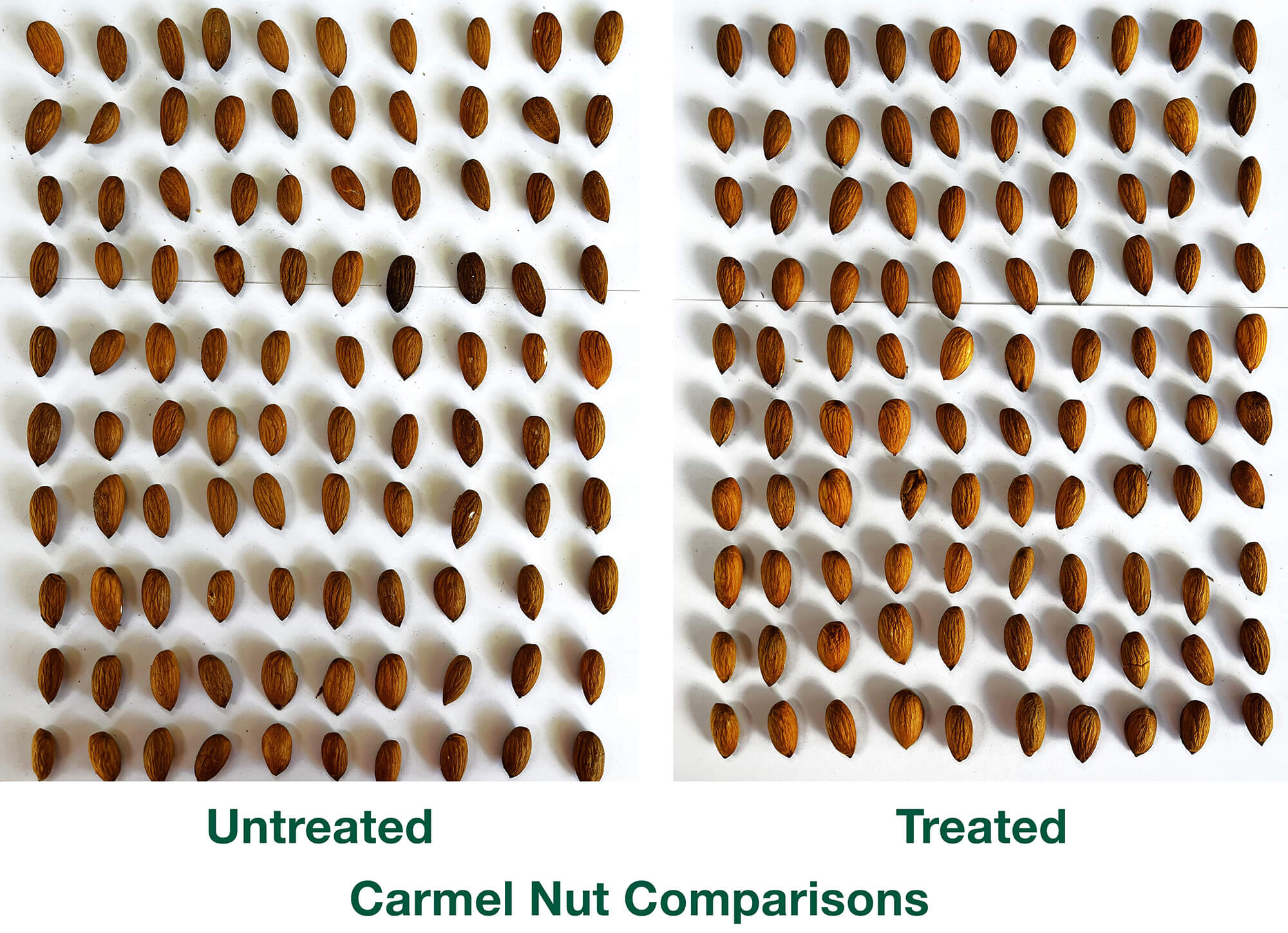

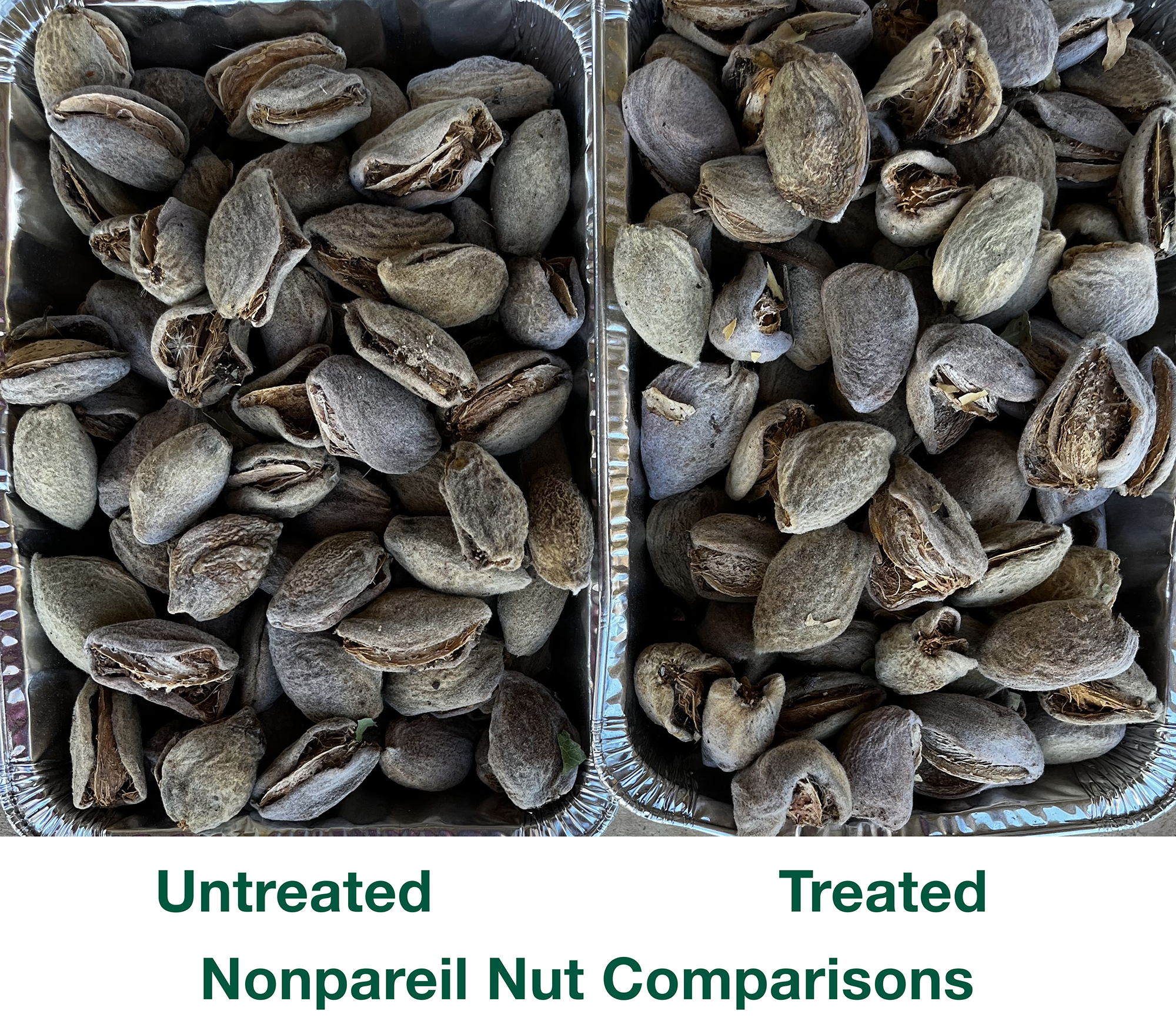

The Almond Orchard employees collected random bunches of Nonpareil and Carmel kernels post-harvest for analysis by BioAg. One hundred kernels of both treated and untreated from each variety were weighed, cracked and nuts were analysed and dried. The results outline that after 8 months of BioAg biostimulant treatments, changes in treatments were obvious.

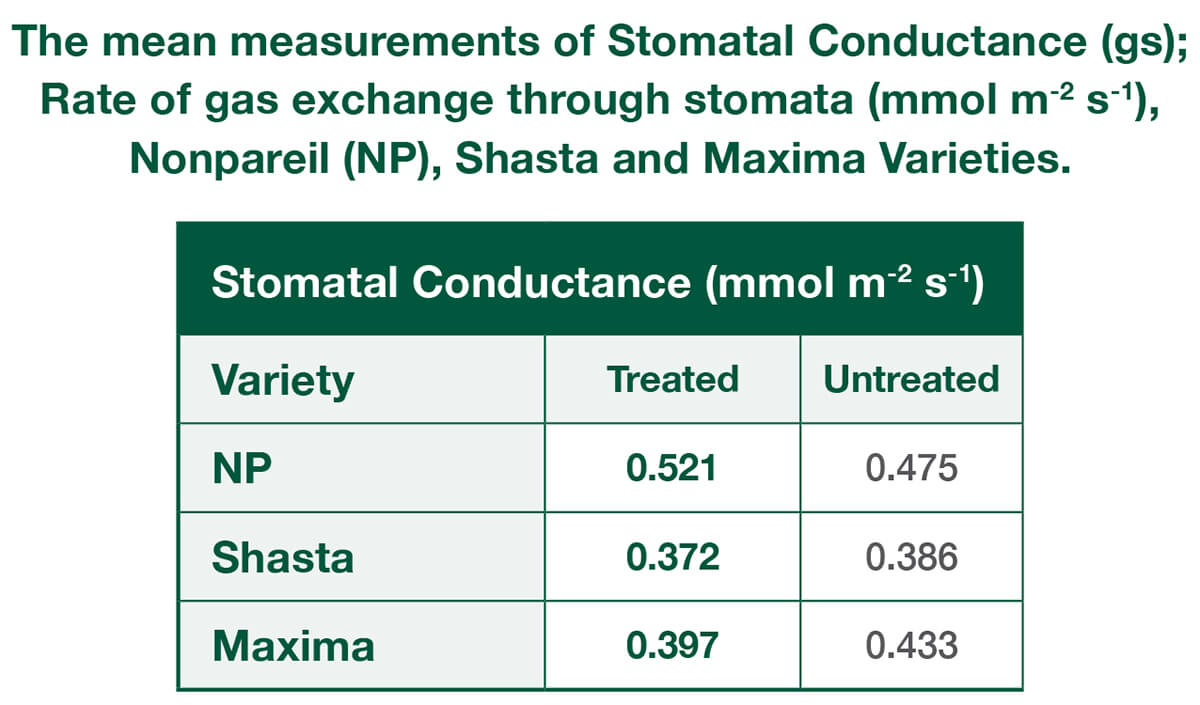

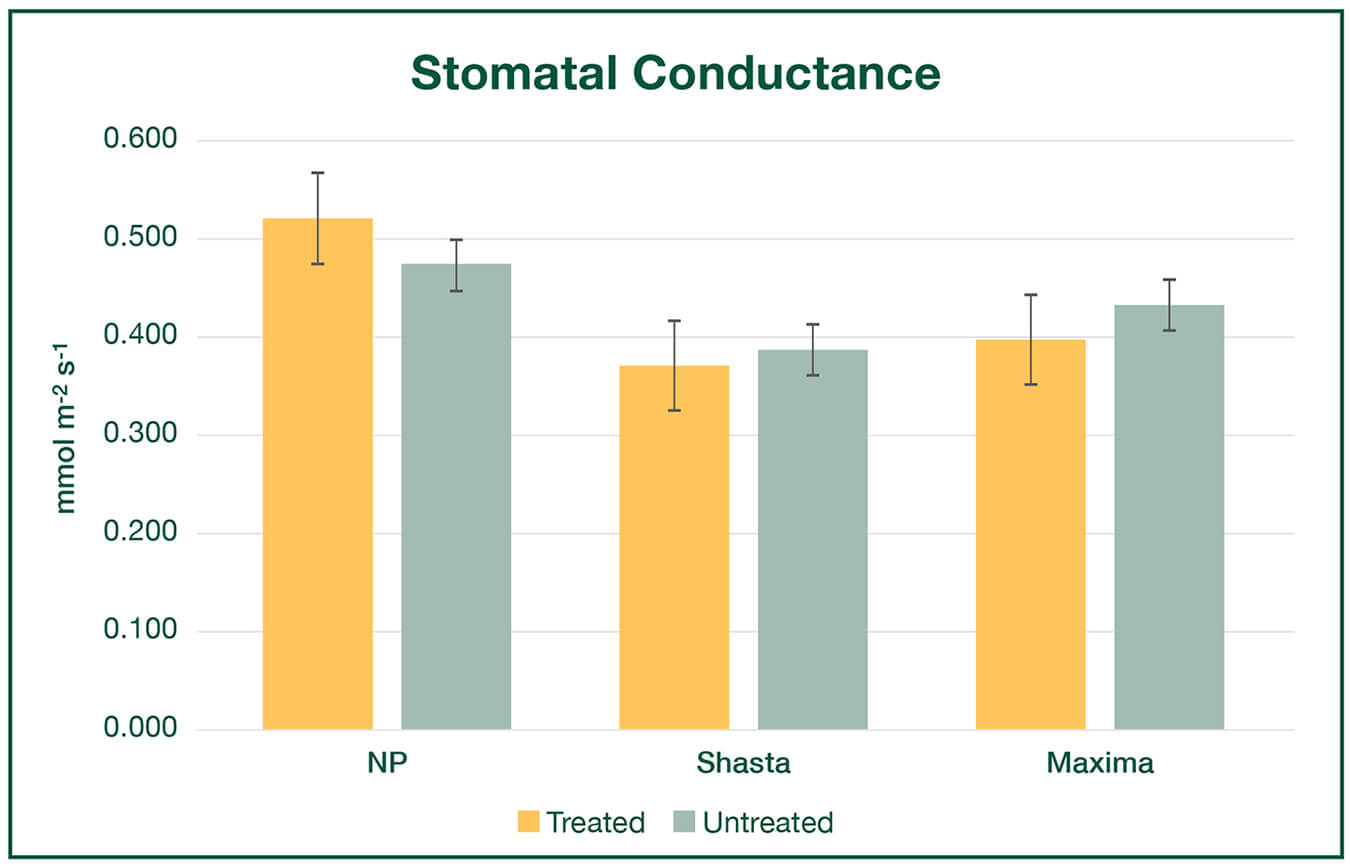

Stomatal Conductance was measured over 80 leaves, per variety, per treatment. No significant differences were observed. This season, there was no nut production and continual irrigation to reduce stress impacts. This will be a good base measurement for the coming seasons.

Stomatal Conductance measurement with Li-cor device.

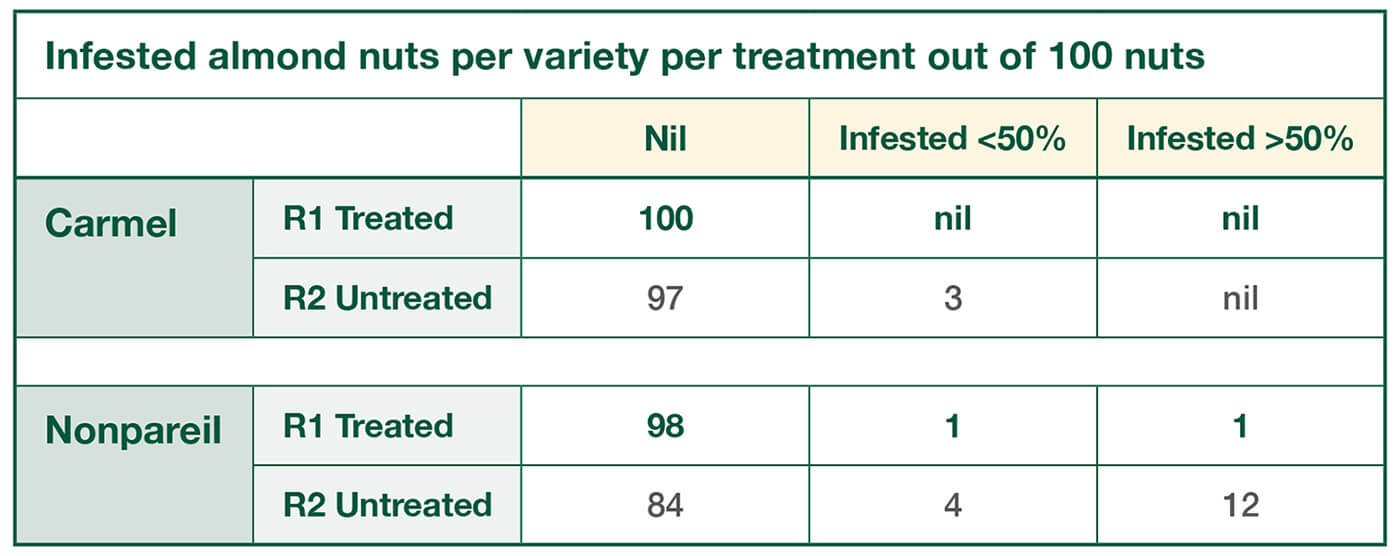

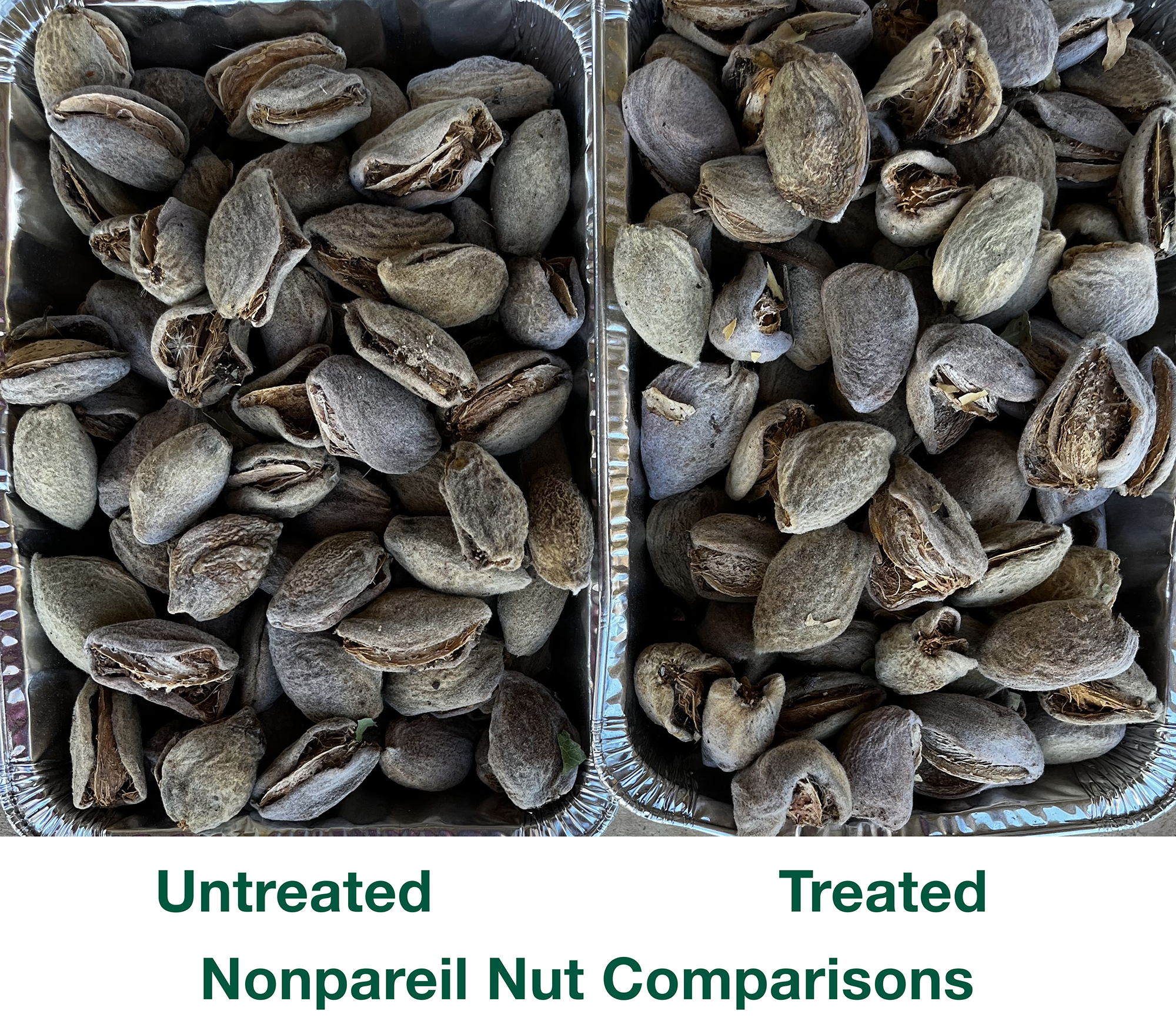

A common observation with Nonpareil treated almonds, were the shells were thicker, had Carob Moths (larvae stage) infestations on the outside of the shell and not inside on the nut, as the hull was much thicker than the untreated nuts. Orchard staff were shown this to observe these differences. These shells did carry more weight, but the overall treated nuts, still had more mass and much lower nut damage infections.

When harvested almond crops are waiting to be processed, the tonnages are in stockpiles on all almond orchards. Insect pests are likely to have been harvested from the orchard and transported to the stockpile where they continue to feed on the almonds. This is where fumigating stockpiles can assist in preventing insect damage while stored on-farm. Research has shown it is difficult to keep the concentration of gas for the required time to kill insects at all life stages in almond stockpiles. The absorption of the fumigant by almond hulls and shells is a contributing factor, hence not all forms of fumigation are effective. (Source: Almond Board Australia).

The one-hundred nuts that were harvested for the BioAg demonstration were kept at room temperature for 6 weeks. Even though these were already hulled, it shows the threat to the almond industry if not treated correctly. Particularly from the Nonpareil BioAg treated nuts (thick hulls and low pest damage), this can help limit the spread and damage by the carob moths.

Many shells had already cracked naturally, and this allows for pest to spread. Images below are the Nonpareil nuts, six weeks sitting at room temperature in bags.

Recent Comments